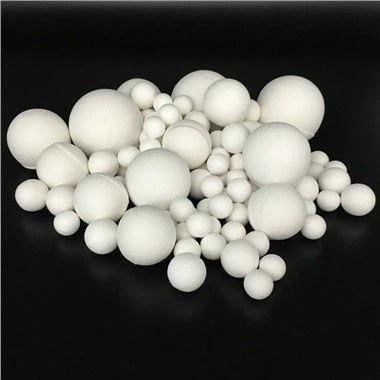

â– Description:

Inert ceramic balls can compensate for temperature variations during production and has strong thermal stability. It is resistant to high temperatures and pressures, low water absorption, stable chemical function, acid, alkali, and other solvents.

â– Specific:

The main functions of alumina ceramic beads are to enhance the diffusion of gas or liquid in a reactor and to support and safeguard the weak activating catalyst.

High Alumina Support Media is in chemical composition92+% alpha alumina and a maximum 0.2wt% SiO2 . Because of its high alumina content and low silica (SiO2 ), it's a very excellent and ideal product for high temperature and steam applications, such as secondary reformers in ammonia processing, where leached silica will coat downstream equipment or foul the catalyst bed.

Color: |

White |

|||

Shape: |

Ball |

|||

Physical properties | ||||

Index |

Value |

Value |

||

Leachable Iron |

≤ 0.01% |

|||

Apparent Porosity by Weight |

≤ 7.0% |

|||

Moh's Hardness Scale |

>8.0 |

|||

Water Absorption |

||||

Acid Resistance |

>99.8% |

|||

Thermal Conductivity |

0.7-0.8 w/m2 .k |

|||

Thermal Expansion @ 500 |

0.10% |

|||

Thermal Shock Stability, 1000 then water cooling |

10 times |

|||

Max. Operating Temperature |

1550°C |

2822 |

||

Specific Density |

3.2g /cm3 |

212 lb /ft3 |

||

Bulk Density (Packing Density) |

1.9 g /cm3 |

125 lb /ft3 |

||

Size |

Crush Strength |

|||

Nominal Size |

(lbs) |

(kg) |

(N/pc) |

|

mm |

inch |

min. |

min. |

min. |

3 |

1/8" |

115 |

52 |

510 |

6 |

1/4" |

230 |

105 |

1030 |

10 |

3/8" |

440 |

200 |

1961 |

13 |

1/2" |

1355 |

615 |

6031 |

16 |

5/8" |

1720 |

780 |

7650 |

19 |

3/4" |

2315 |

1050 |

10297 |

25 |

1" |

3130 |

1420 |

13925 |

38 |

1-1/2" |

4034 |

1830 |

17946 |

50 |

2" |

4960 |

2250 |

22065 |

â– Application:

1. High purity and high strength.

In the reactor, it is better to avoid the leached silica covering the downstream equipment or forming dirt or poisoning the catalyst carrier.

2. Low water absorption and stable chemical performance

Increase the distribution points of gas or liquid to support and protect the active catalyst with low strength.

3. High alumina content and low silicon dioxide (SiO2)

Ideal for high temperature and steam applications

For example, in the secondary reformer of ammonia treatment, the leached silica will cover the downstream equipment or pollute the catalyst bed.

4. High aluminum carrier medium has very excellent thermal performance, and its high-density high temperature resistance can reach 1550 ℃, which is also a good choice for thermal insulation or deceleration media

5. Inert chemical properties

Applicable to olefin processes with polymerization problems, such as ethylene dryer

http://www.zbshell.com/

By certification

By certification